Axle Info

|

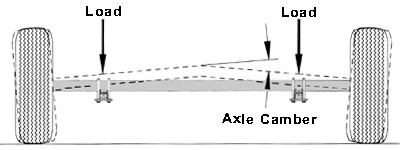

Axle Camber |

| The angular relationship of the wheel to the

road surface in the vertical plane. Axles are typically built with a

pre-determined bend in the tube that compensates for the expected

deflection under load. Ideally, the tire footprint will contact the

road evenly across the width of the tread.

|

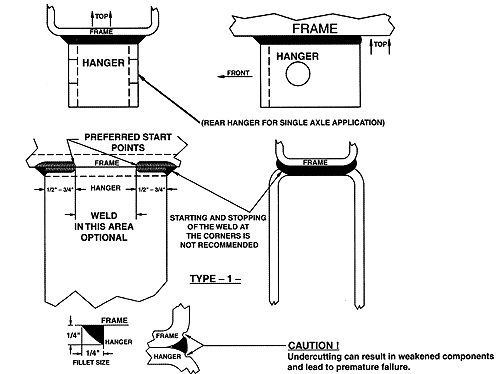

| Hanger Installation |

| Most hangers are channel shaped steel stampings, designed to

be welded to the underside of the frame rails to provide the attaching

points for the leaf springs and their associated parts. The

attaching parts are normally provided in kits,

which contain all the necessary hardware to properly install the running

gear. In the case of multiple axle installations, equalizers

are often used to help transfer load from one axle to the other(s) as the

trailer moves over uneven terrain. Not all combinations of

equalizers are suitable. If the equalizer hangers are too

short, the spring eye may contact the frame during articulation of the

suspension and result in overloading of the spring.

Over tightening the nuts can lead to fastener failure. The torque specification for the 7/16" - 20 Hex nut used on shouldered shackle bolts is 30 - 50 lb. ft. The nut should not be used to "pull" the shackle bolt into the hanger. Instead, the bolt should be driven into place to allow the serrations to grip the hanger. Using an impact wrench without some type of torque limiting device can damage the threads and the serrations. Shackle bolts that are free to rotate will severely limit the service life of the hangers.

|

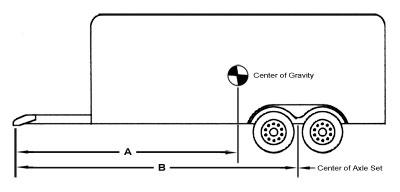

| Dimensional Requirements |

Where to locate the axle set on trailer

frame.

Note: "Center of Axle Set" on a Torflex axle is defined as the center of spindle.

|

|

Spring Suspension Comparison |

|||

| Double Eye Springs | Slipper Springs | ||

|

|

|

||

| Pros | Cons | Pros | Cons |

|

|

|

|